Category

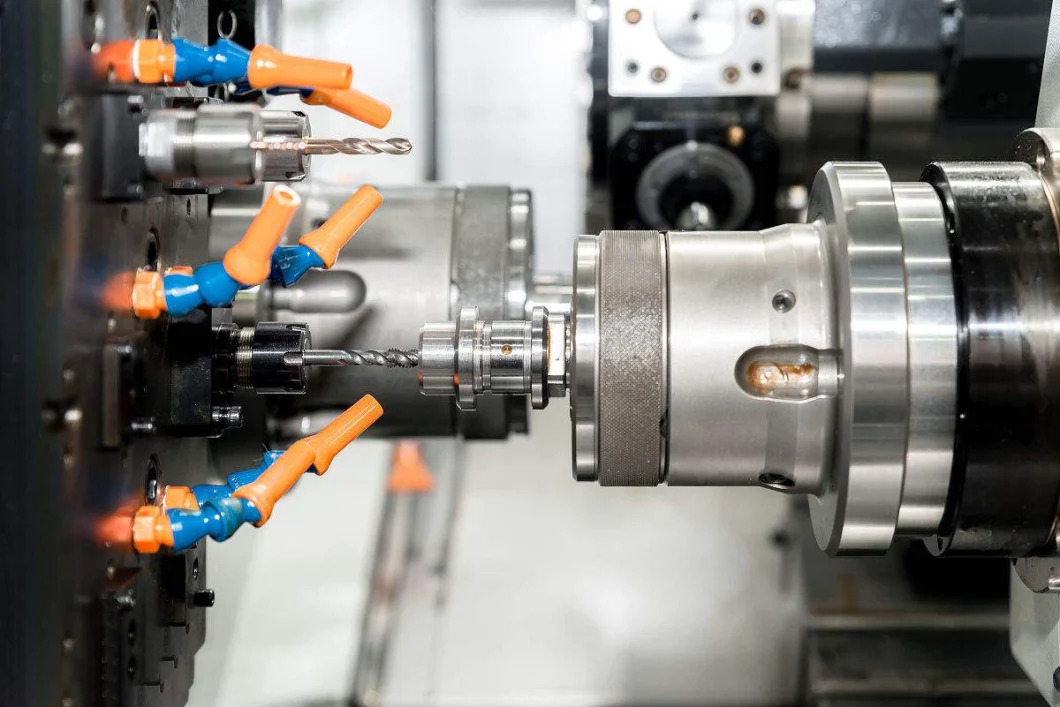

High Precision of CNC Milling Turnling Machining Service Custom Metalwork Lathe Processing Professional OEM Factory

Provide China CNC Machined Machining Parts Lathe Processing Parts 1. Machining parts description Machinery parts for Aut

Basic Info.

| Model NO. | TONLO machining |

| Transport Package | The Cartons |

| Trademark | TONLO |

| Origin | China |

| HS Code | 7326901900 |

| Production Capacity | 30000PCS/Year |

Product Description

Provide China CNC Machined Machining Parts Lathe Processing Parts

1. Machining parts description

Machinery parts for Automobile engine, furniture, agriculture, and so on

Strictly control every step of production process including product planning, R&D, engineering, inspection, experience.

| Item | Small stainless steel metal turned machine parts customized on 3d drawings |

| Material | 1.Stainless Steel:AISI303, AISI304, AISI316F, 420,440,etc. |

| 2.Aluminum: Al6061, Al6063, Al7075, Al6082,etc. | |

| 3.Brass:C36000, C37700, Hpb59-1, H62, C27200(CuZn37),etc. | |

| 4.Steel: carbon steel, alloy steel, etc. | |

| 5.Copper | |

| 6. Plastic : PVC, POM, Nylon etc. | |

| Process type | CNC turning, milling, drilling, grinding, wire EDM cutting etc. |

| Dimensions | According to your supplied drawings |

| Tolerance | According to ISO2768-m, or client request |

| Applied Software | PDF, Steps, Stp , UG, CAD are all avialable |

| Packing detail | Euro pallets /Carton boxes |

| As customer's request | |

| Trial sample time | 7-days after confirmation |

| Delivery time | 7-30 days after receive the pre-payments |

2. Research & Development Ability

Chongqing Sipx Machinery Co., Ltd More than 12 years in machinery industry, our core team members are good at machinery parts R&D, familiar with TS16949 system, TPS(Toyota production system), Lean production. To fulfill OEM outsourcing parts requirement from all over world customer, we would like to share our professional technology and quality management experience, our aim is to optimize customer's design and reduce cost based on different process technology.

| Our services | |

| Technology and service | 1. Can carry on the synchronized development design according to the user's needs. |

| 2. Technical consultation | |

| 3. Strictly TS16949 quality control system | |

| 4. 7days 24 hours on line service | |

| 5. Perfect material purchasing chanels | |

| 6. Look for better way to reduce cost | |

| 7. PPM≤60 | |

| Software | UG, Catia, ProE, Solidworks, AutoCAD |

| R&D | 10 persons |

| Cooperat with Chongqing university and other professional orgnizations | |

| Management model | Project management |

| Application: | Automobile, Motorcycle, Brake system parts, Transmission parts, Automobile intake system R&D |

3. Manufactures Ability

Much of modern day Machining is carried out by computer numerical control (CNC), in which computers are used to control the movement and operation of the mills, lathes, and other cutting machines.

| Material | Carbon steel, Alloy, Stainless steel, Brass, Powdermetallugry, Mould material |

| Process | Turnning, milling, grinding, drilling, tapping, boring, EDM, wire cutting, heat treatment |

| Surface Treatment | Anodizing, polishing or others |

| Application | Mould, Automobile, Motorcycle Engine Components, Brake System Parts, etc. |

4. Inspection Ability

· IQC IPQC FQC QE

· CPK>1.67 for significant dimensions

· Siginificant process should 100% checking for your machining parts

| Experience Equipments | High-low temperature equipment |

| vibration test stand | |

| Durability test | |

| Performance simulation test bench | |

| X-ray material testing equipment | |

| Hardness testing | |

| Roughness testing | |

| Other special customized experience equipments for your machining parts |

5. Declaration

The showed part just part of our products, but we not only sell these products, we offer the service and skills. We are specialized in sheet metal processing more than 12 years. We are more professional and serious. We import advanced laser cutting machines, welding machines, CNC machines, bending machines and so on form Japan and Germany. We are very famous in printing powder coat in China. It will help us to reduce the cost.

Please show us your DRAWING &SAMPLES, we will produce it as you need.

BTW, not all steps machining parts make in our own company, no matter we do in our own factory or outsourced, we will 100% check the dimensions, generally speaking stamping parts, punching parts and sintering parts can be done in our own factory.

| 1. Inquiry-Professional quotation. |

| 2. Confirm the price, lead time, artwork, payment term etc. |

| 3. Freedom sales send the Proforma Invoice with Sifit seal. |

| 4. Customer make the payment for deposit and send us Bank receipt for your machining parts |

6.Equipment